Feeling uncertain about the custom packaging setup, If actually make sense for your product?

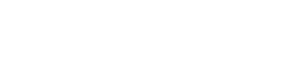

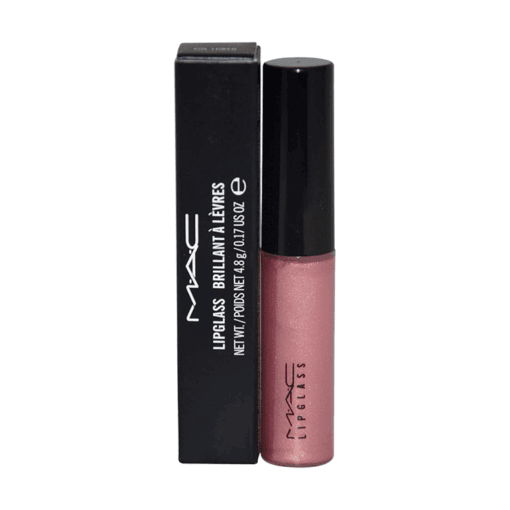

If you have ever dealt with custom packaging, you already know the common problems. Boxes that don’t fit right, CMYK Colors are printed incorrectly, showing a blurry effect, materials that feel wrong for the product, and Images that looks fine on screen but prints pixlated, or quotes that change once production starts.

Packaging Boxes Pro helps you avoid those issues in the first place. Instead of selling pre-set box types, we look at how your product is packaged, stored, shipped, and sold, then build the packaging around that. Our goal is simple: Deliver packaging that works the first time, without costly revisions or production/shipping delays.

You don’t need to be a packaging expert to work with us. If you know your product size, estimated quantities, and how the box will be used, we can take it from there. From structure and material to print setup, we make sure everything is aligned before production begins.

Below are some of the packaging solutions we commonly build for brands, retailers, and manufacturers.

Read More

Frequently Asked Questions

Do you offer fixed pricing or standard packages?

No. Every project is different. Pricing depends on box style, material, printing, quantity, and logistics. This approach keeps things realistic and avoids paying for features you don’t actually need.

What do you need from me to get started?

At a minimum: product dimensions, target quantity, and how the packaging will be used (retail, shipping, or both). If you have existing packaging, we can work from that as well.

Can you match our current packaging or supplier specs?

Yes. We often match existing box sizes, materials, and finishes — especially for businesses looking to improve consistency, lead times, or cost control.

I don’t have artwork ready. Is that a problem?

Not at all. If you already have artwork, we’ll review it for print accuracy. If not, we’ll guide you on setting it up correctly or provide a template so nothing breaks during production.

How do you make sure there are no production issues?

We review structure, material strength, and print setup before anything goes into production. This helps prevent common problems like crushed cartons, color mismatches, or sizing errors.

Who do you typically work with?

We mainly work with businesses that need reliable, repeatable packaging — including brands, manufacturers, and retailers — rather than one-off or template-based orders.

How long does production usually take?

Timelines vary depending on the packaging type and print complexity. We confirm production and shipping timelines before order approval so expectations are clear from the start.